TRIO

TRIO Motion Technology is a manufacturer of Motion Coordinators, Servo Systems (drives & motors), HMIs and SCARA robots.

Home / Products / Drives & Controls / TRIO

TRIO Motion Technology

Trio Motion Technology was founded in 1987 as a manufacturer of motion controllers. Today the range, branded Motion Coordinators, can control up to 128 axes of servo, stepper and piezo motors as well as hydraulic systems. Trio’s expertise of motion programming is based within its Motion-iX technology. Launch of the new DX4 servo drive and motor packages now develops Trio’s offering into a motion solution in addition to providing motion controllers for automation vendors and system integrators. In addition to the Motion Coordinator line, Trio now offers a complete line of servo drives and drives, along with a full range of SCARA robots; providing customers with a motion-centric machine solution.

Motion Coordinators

The Motion Coordinator system allows you to control up to 128 servo or stepper motors with Digital I/O and additional equipment such as HMI’s all controlled from a single master. Systems may be used with a stand alone program or alternatively commands can be sent from an external computer..

Conventional

The MC Series of Motion Coordinators from TRIO offer users the ability to interface their servo drives with any MC controller to create synchronized motion.

- MC403 – 2 Axes (Extended Axes, 3 Total)

- MC405 – 5 Axes

- MC508 – 8 Axes or 15 Step/Dir

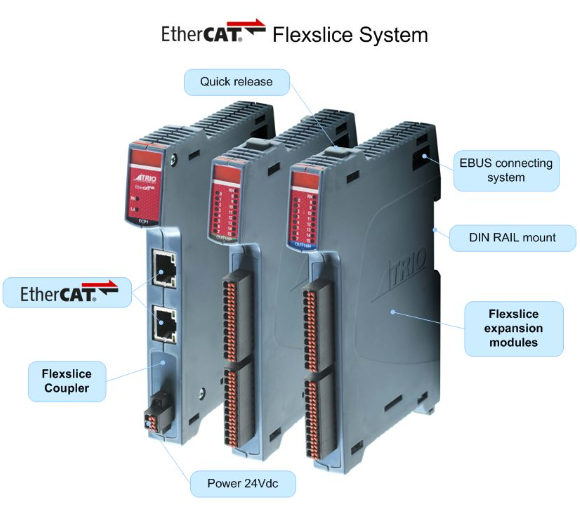

EtherCAT

EtherCAT (Ethernet for Control Automation Technology) is an Ethernet based fieldbus designed/adapted specifically for automation technologies.

- MC644 – 128 Axes of Control

- Flex 6 Nano – 64 Axes of Motion with matching slices for inputs, outputs & axes modules.

- MC MCAT – Motion Coordinator on a windows PC.

RTEX – Panasonic

Real Time Express (RTEX) is a proprietary feedback unique to Panasonic, where teh data is exchanged in a different format than that of Ethernet.

- MC664 – Single & Quad Core up to 128 Axes

- MC4N RTEX – Mini Master (2-32 Axes)

Downloadable Documents

Servo Drives

The commissioning of DX Servo Drives is made simple with a series of Device Configuration Screens allowing access to status information and diagnostics at a glance. All motor axes can be detected, setup, monitored and controlled in real-time from the easy to use dialogue windows.

DX4 – AC Servo Drives

Introducing Trio’s solutions with the new DX4 servo drives, our all new drive and motor packages that provide performance and dependability, optimized in every detail to do more with less. EtherCAT Support with update rates down to 125us.

- DX4-101A – 100W

- DX4-102A – 200W

- DX4-104A – 400W

- DX40108A – 750W

- DX4-110A – 1kW

- DX4-115A – 1.5kW

- DX4-120A – 2kW

- DX4-130A – 3kW

Downloadable Documents

DX5 – AC Servo Drives

200V AC Servo Drive Systems – Trios’ multi-axis AC servo drive

- DX5-06KA – 3 Phase, Power Supply Module

- DX5-20404AEA – Dual 400W axis Module (100W 200W & 400W)

- DX5-20808AEA – Dual 750W axis Module (400W & 750W)

Downloadable Documents

Servo Motors

TRIO offers a wide variety of both medium inertia and low inertia motors. With power ranges from 50W to 3kW, these motors can be configured with optional brakes, incremental or absolute encoders and paired with matching cable sets and drive options. These servo drive systems can be used in a wide range of applications thanks to their high performance, available power range and compact dimensions.

MXM – Medium Inertia & Speed

The MXM family of servo motors are suitable for application speeds up to 3000 rpm, include variants with an integrated brake. Medium inertia allows fast response times and these motors develop a very high torque despite their small size. Ideal for applications with high dynamic responses and fast and precise positioning.

- Power Ranges – 1kW to 3kW

- Flange Sizes – 130mm & 180mm

- Encoder Options – 20-bit incremental or 23-bit absolute encoder

- Voltages – 200 & 400 Vac

- Additional Features – IP65 Rated, Oil seal as standard, Optional Brake

Downloadable Documents

MXL – Low Inertia & High Speed

The MXL family of servo motors are suitable for application speeds up to 6000 rpm, include variants with an integrated brake. Low inertia allows very fast response times and these motors develop a very high torque despite their small size. In combination with our servo drives, they are ideal for applications with high dynamic responses and fast and precise positioning.

- Power Ranges – 50W to 1kW range

- Flange Sizes – 40mm to 130mm

- Encoder Options – 20-bit incremental or 23-bit absolute encoder

- Voltages – 200V & 400Vac

- Additional Features – IP65 Rated, Oil seal as standard, Optional Brake

Downloadable Documents

Robotics

Building on the success of Trio’s Robot Programming System (RPS), Trio now have a range of SCARA robots. A component based SCARA offer, integrating Trio SCARA with Trio Controllers, Trio drives and Motion Perfect. Flexible, integrated and easy to use.

SCARA

Rapid application development of controller, SCARA and DX drive configuration within Motion Perfect.

- D1000 – 1kg rated, 3kg max, IP20, 400mm reach

- D1001 – 2kg rated, 6kg max, IP20, 500mm reach

- D1003 – 2kg rated, 6kg max, IP20, 600mm reach

- D1003 – 2kg rated, 6kg max, IP20, 700mm reach

Downloadable Documents

Linear Encoders and Feedback Devices require a drive/control to process the signal.