Cymatix Motors

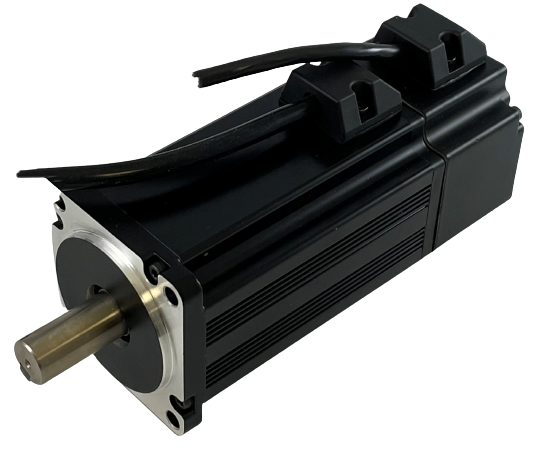

Cymatix has been solving applications in automation and motion control since 1983 and in that time has gained a tremendous amount of experience in motors and motor control. We have leveraged this experience to provide our own family of motors. Offering both Nema and Metric frame sizes and custom designs.

Home / Products / Motors / Cymatix Motors

Cymatix Motors

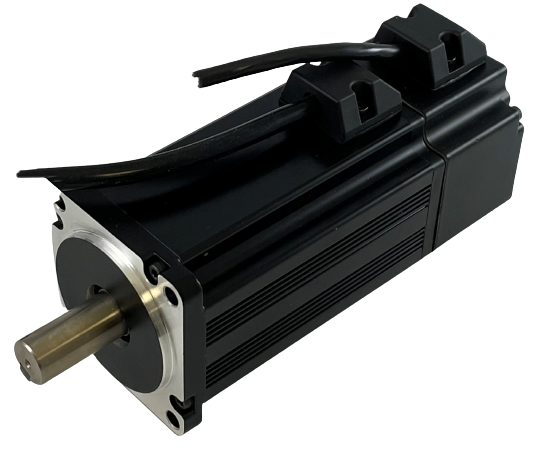

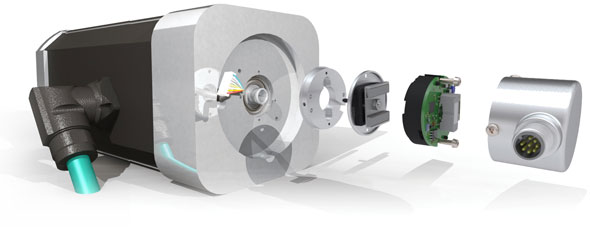

At Cymatix, we have leveraged our 40+ years of industry experience to not just help customers size/select rotary brushless servo motor solutions but the ability to provide custom motors and configurations to best meet application demands. We stock various stack lengths, encoders, brakes, and connectors that can be assembled locally in Petaluma, CA. By offering a modular design, we can generate hundreds of configurations of motor solutions based on inventory components and for unique applications where we don’t have a solution on the shelf our team of industry experts are here to help and will design a custom solution that is uniquely tailored to meet your needs.

Quick Ship

Custom Motors

Brakes & Accessories

Quick Ship Motors

Using our 40+ years of industry experience we know the common application requirements and have done our best to generate a family of motors which we stock in Petaluma and can assemble to meet your needs. Our unique design is modular in nature, meaning that we can configure the same motor with different stack lengths, encoder options, cable lengths based on requirements and brake options. Once a motor configuration is generated, we submit this to our team of experienced technicians to assemble your motor; this process on average takes 2-3 weeks. Expedite options are available.

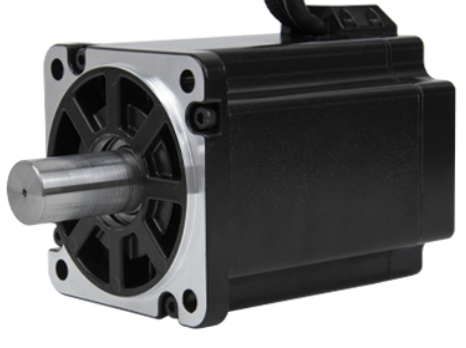

Metric Frame Sizes

Metric Performance (MP) servo motors come in three different sizes (24mm, 60mm & 80mm). These motors are designed with zero cogging torque which makes them great for applications involivng low velocity ripple. Each motor can be configured with custom connectors and offer different encoder & brake options.

- MP24: 24mm, 30W, 0.1Nm

- MP60: 60mm, 400 or 540W, 1.3Nm

- MP80: 80mm, 765Watt, 2.4 Nm

| Motor Part Number | Flange [mm] | Length [mm] | Voltage [Vdc] Rated / Peak | Torque [Nm] | Speed [rpm] | Power [Watts] | Encoder Res [ppr] |

|---|---|---|---|---|---|---|---|

| MP24-2B-MX2500-NN-01 | 24 | 58 | 24 / 170 | 0.1 | 3000 | 30 | 2500* |

| MP60-3A-MX5000-CN-001 | 60 | 143 | 48 / 170 | 1.3 | 4000 | 540 | 5000 |

| MP60-3B-MX5000-CN-001 | 60 | 143 | 72 / 310 | 1.3 | 4000 | 540 | 5000 |

| MP60-3C-MX5000-CN-001 | 60 | 143 | 170 / 310 | 1.3 | 3000 | 400 | 5000 |

| MP80-2B-BX2500-CN-001 | 80 | 153 | 310 / 310 | 2.44 | 3000 | 765 | 2500 |

| MP80-2B-BX2500-CB-001 | 80 | 190 | 310 / 310 | 2.44 | 3000 | 765 | 2500 |

Nema Frame Sizes

Brushless Servo motor, 30 Watts to 765 Watts. Configurable with optional BISCC-C Absolute encoders as well as optional brake options.

- Nema 17: Single, Double & Triple Stack

- Nema 23: Single, Double & Triple Stack

- Nema 34: Double Stack

| Motor Part Number | Flange [mm] | Length [mm] | Voltage [Vdc] Rated / Peak | Torque [Nm] | Speed [rpm] | Power [Watts] | Encoder Res [ppr] |

|---|---|---|---|---|---|---|---|

| E017-1A-MX5000-NN-001 | 42 | 53 | 24 / 170 | 0.1 | 3000 | 30 | 5000* |

| E017-2A-MX5000-NN-001 | 42 | 72 | 24 / 170 | 0.2 | 3000 | 60 | 5000* |

| E017-3A-MX5000-NN-001 | 42 | 90 | 24 / 170 | 0.3 | 3000 | 90 | 5000* |

| EP23-1A-MX5000-CN-001 | 57 | 71 | 72 /170 | 0.39 | 6000 | 220 | 5000* |

| EP23-2A-MX5000-CN-001 | 57 | 97 | 72 / 170 | 0.63 | 5250 | 350 | 5000* |

| EP23-3A-MX5000-CN-001 | 57 | 122 | 72 / 170 | 0.78 | 5750 | 467 | 5000* |

| EP34-2A-MX2500-CN-001 | 82 | 153 | 48 / 170 | 2.44 | 3000 | 765 | 2500* |

| EP34-2B-MX2500-CN-001 | 82 | 153 | 310 / 310 | 2.44 | 3000 | 765 | 2500 |

Custom Motor Solutions

If one of our “Quick Ship” motors will not meet your application, we are more than happy to work up a custom design to meet your application requirements. We have the expertise and industry knowledge to provide you with a custom solution. The process starts by reviewing your specifications with one of our industry experts, where together we will generate a scope of work outlining the critical specifications required. Examples of custom motors include providing a drop in solution for an existing motor which has since become obsoleted or no longer performing as expected. When it comes to custom, we can provide not only a custom solution but one that is cost competitive as well.

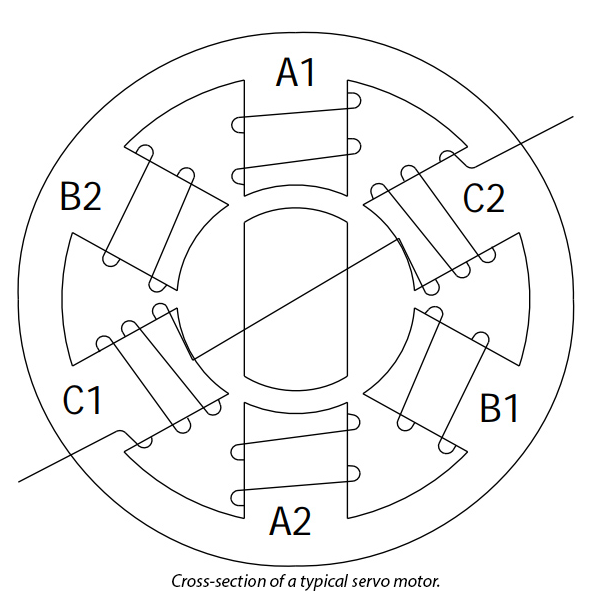

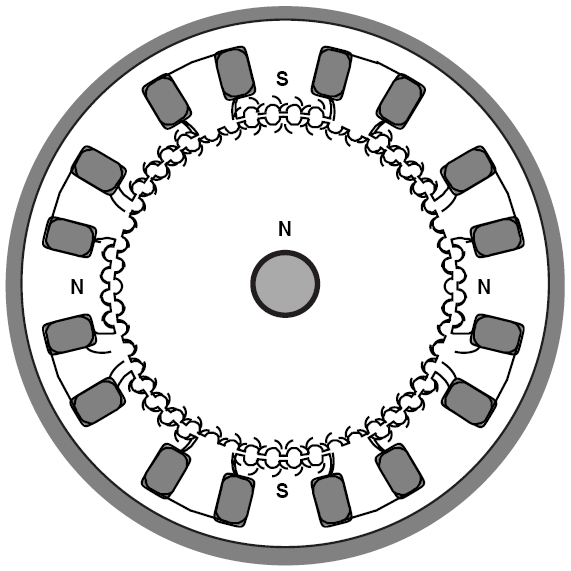

Rotary Servo

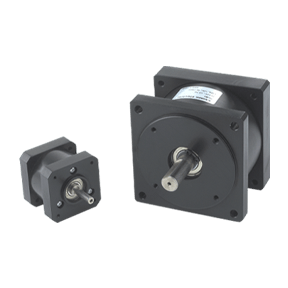

Brushless DC motors come in both two phase and three phase configurations. Motor designs for a custom BLDC (brushless dc motor) require understanding required speed, axial loadings, torque requirements, envelope/size constraints, encoder resolution, voltage, back EMF and duty cycle are a few of the specifications our team will review with you to ensure that we provide the best solution for your application. Including gearmotor solutions.

Rotary Stepper

Stepping motors come in a variety of shapes and sizes and our team of engineers will work with your team to ensure that our motor solution is optimized for your application.

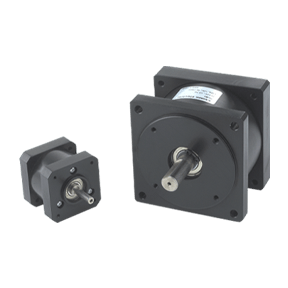

Brakes and Accessories

In addition to proving both off the shelf and custom motor solutions we also provide the ancillary components that go with them. We can provide electro-mechanical brakes for vertical and safety applications as well as provide custom cable sets that are built to mate your motor and drive and to the desired lengths needed. Furthermore, if you purchase your motor and drive from us, we will generate the pin-out schematic and prior to shipping will test your motor using your new drive and provide PID suggestions for tuning.

Electro Mechanical Brakes

For vertical applications and applications requiring safety, adding an electro-mechanical brake prevents rotation of the motor preventing any unintended slipping or back driving of the load. Another advantage of using an electro-mechanical brake is keeping the motor cool instead of having the motor servo’ing to hold position. Our electro-mechanical brakes are easy to implement by mounting to the front of the motor and once activated by applying a voltage the breaking mechanism releases. When a voltage is not detected the brake mechanism locks preventing rotation of the shaft.

- Nema 17 (42mm): 0.113 Nm rated

- Nema 23 (57mm): 0.5-0.8 Nm rated options

- 60mm Frame: 1.5 Nm rated

- Nema 34 (82mm): 1.7 Nm rated

| Motor Brake PN | Flange [mm] | Length [mm] | Torque [Nm] | Voltage [Vdc] | Shaft Input [mm] |

|---|---|---|---|---|---|

| BPC017-21-003 | 42 | 49 | 0.113 | 24 | 5 |

| BPC023-24-027 | 57 | 48 | 0.5 | 24 | 6.35 |

| BPC023-24-026 | 57 | 62 | 0.8 | 24 | 6.35 |

| BPC024-24-002 | 60 | 70 | 1.5 | 24 | 14 |

| BPC034-24-003 | 82 | 78 | 1.7 | 24 | 12.7 |

Encoder Kits

We offer a wide variety of encoder options, including both incremental and absolute as well as their associated technologies of optical and magnetic. If you have an existing motor with a rear shaft and are looking to add an encoder, please let one of engineers know and we would be happy to provide you with a solution that will mate mechanically, provide the encoder resolution needed and in the format that your system can read.

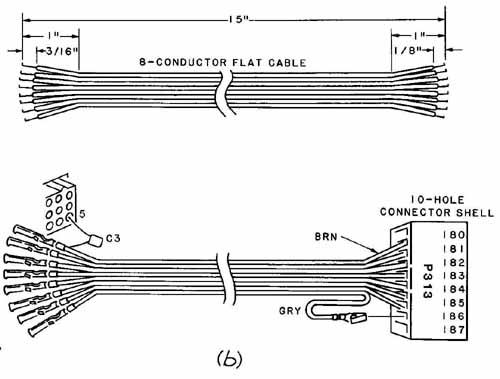

Cable Sets

Our team of technicians have 20+ crimping tools as well as a variety of wire reels to choose from, allowing us the ability to provide a variety of connector and wire configurations. Furthermore, our team of engineers will work with your team to ensure proper grounding and noise prevention is incorporated into the design. Our objective at Cymatix is to ensure your application success. We have found that providing the cable pre-configured to mate your motor and drive ensures faster testing and optimal performance.

Servo motors require drives/controls to operate.

Cymatix Motor Filter/Selector & Downloads

Cymatix Motor Filter/Selector & Downloads