Our Process

We are more than just product suppliers, we are consultants in motion, who leverage our industry experience and knowledge to ensure your application’s success. Our process begins with our engineering team reviewing your application and ensuring all attributes are understood.

How we approach new and existing applications

Whether you are working on a new machine or retrofitting an existing one, our process helps us ensure application success and ensures no details are overlooked. As a distributor of more than twenty motion control manufacturers, we are able to solve applications in a variety of ways. By teaming with your engineers and knowing the application inside and out, we can filter out solutions and strategies that just don’t make sense, allowing us to present solutions that best meet your application needs. Often there are a variety of solutions and strategies that can be selected, each has its own unique set of properties, of which our team will review with you highlighting unique properties such as size, envelope, speed, accuracy, repeatability, budget, lead time, complexity etc.

Our 5-Step process was designed to ensure your application’s success. Our team of engineers act as an extension of your team, providing consultations, design reviews, technical product suggestions and help in sizing and selecting components. It is our belief that your success is our success and we are dedicated to providing you with the best solution for your application.

Step 1: Application Overview (what are we trying to solve?)

Here we view the application from a macro-level to process and understand what it is we are trying to accomplish.

The purpose behind this part of the process is for our team of engineers to understand the application. By having insights to the application, we can ensure that we are providing you the best solution for your application.

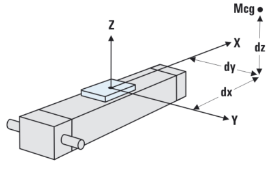

Step 2: Quantify the Application (what specs are needed?)

Next we dissect the application and convert macro designs into specifications and requirements; i.e. we are trying to move something that weighs this much, this far, this quick, and with a certain accuracy.

The purpose behind this part of the process is to understand what the application requires from a technical standpoint (accuracy, repeatability, environmental concerns etc.) as well as commercial standpoint (pricing and lead time expectations).

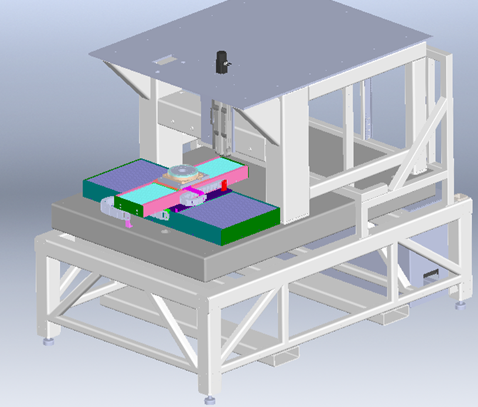

Step 3: Design & Present your custom automated solution

Using the information gathered in steps 1 and 2, we will present you with a complete bill of materials, where each part was carefully selected based on engineering, calculations, specifications and commercial attributes including price & lead time. Spec sheets and CAD models will also be available at this step.

Step 4: Our Value-Add Proposition

Once an order is placed, most orders go through our Value-Add Department where custom cables are built, components are assembled to make sub-assemblies, drives are configured, and motors are tuned. When we ship, we strive for “plug & play” simplicity; anything to make your life easier.

Step 5: Post-Sales Support

Our team of engineers will work with your team to ensure application success. We will do zoom calls and on-site visits to troubleshoot and support you through any hurdle you may encounter.