Gearboxes

Gearboxes are mechanical assemblies that increase the torque of a motor by reducing its speed and in doing so, combating inertia. In a well-designed system, the inertia of the load being driven should be no more than 10 times that of the motor’s rotor; when a gearbox is implemented the inertia of the load is reduced by the square of the gearbox ratio. If the inertia mismatch (load to rotor) exceeds 10:1, the load is hard to control and positioning becomes challenging.

Reducers

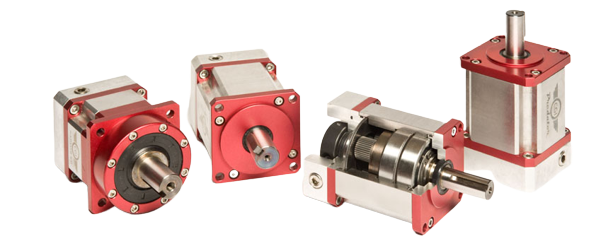

CGI

CGI Precision gearheads are available in NEMA sizes 17 to 75. Metric equivalents are also available. Standard ratios ranging from 3:1 to 700:1, in planetary and spur designs, with custom shafts and multiple mounting options, are offered in right-angle, in-line, and offset configurations. The Predator, Raptor, and Prime gearheads have a five-year warranty. Custom gearing design and fabrication are also available.

GAM

A source for robotic and servo gear reducers, zero backlash drives, rack & pinion systems, servo couplings, linear mounting kits, and other precision mechanical drive solutions used in motion control and automation technology. GAM offers a wide range of standard products as well as the engineering expertise and manufacturing capabilities to provide customized solutions. All products are manufactured in the U.S.

Source Engineering, Inc

Source Engineering’s economical reducers provide highly reliable power transmission for general purpose applications. Designed and manufactured with cost in mind these reducers offer cost effective operation and superior performance over similar products.

Gearboxes are implemented to increase torque, reduce speed and combat inertia mismatch. Having a well sized motor and gearbox solution is crucial to achieving effective/snappy motion control.